Intelligence, Precision, Trust

With The Standard, dairy, beverage, and food manufacturers can trust

that their product is always in specification while maximizing profitability.

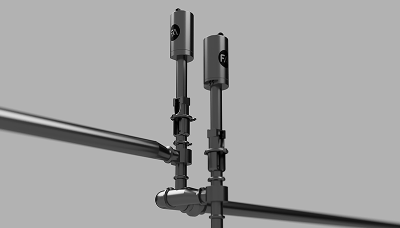

A System That Learns and Adapts

Algorithms that adapt to changing conditions, including milk composition.

Accurate blending, precise control, customizable flows.

Technology that’s constantly watching and improving.

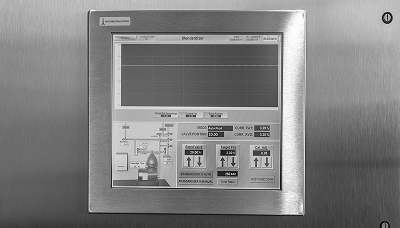

Constant Learning

The Standard saves all its results and constantly learns to accurately set blending equipment to create the best product possible.

Factors like seasonal raw material, changes or effects of surrounding processes are learned.

No more wobbling after every separator desludge, silo change, or making bad product until the system settles in.