CIP Systems affect every aspect of production and the quality of your products.

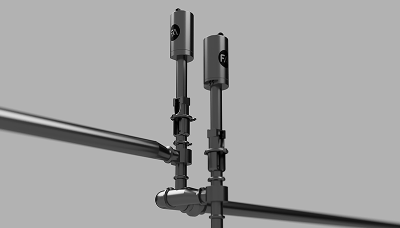

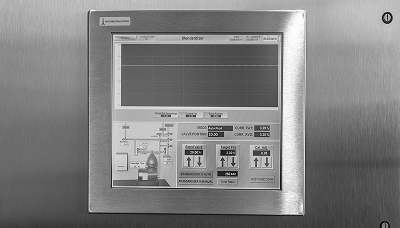

Food Automation’s CIP Systems are designed and build to serve this critical need.

Designed, build, programmed, and tested at our manufacturing site. Our systems are delivered ready to be reassembled and put into production.