Precision Cream Control

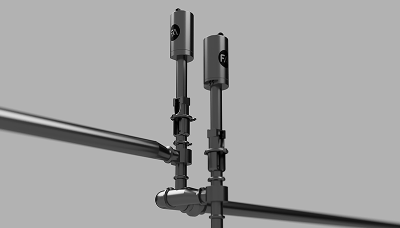

Using technology from The Standard, precision control of the cream density is accomplished.

In line density measurement, with proprietary algorithms offer automatic and repeatable cream control.

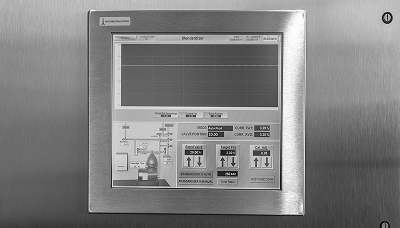

Cream Control You Trust

Controlling the pressures and cream density in your separator process can make a big difference in additional cream sales or final product quality.

Enables consistent cheese manufacturing, reliability for fluid milk bottling, maximizing cream sales in powder drying, accurate product blends for cultured products, and improving separation for ice cream.